solidworks 3d part to 2d drawing

When creating 3D models for 3D printing, nosotros recommend taking the 3D printing procedure into account at all times. Smart modeling prevents 3D printing imperfections, weak areas, and minimizes the use of back up material.

Some tips:

-

Adding small fillets to internal corners makes the printed part much stronger.

-

The minimum wall thickness for stereolithography (SLA) 3D printing is 0.6 mm, for selective laser sintering (SLS) 3D printers it is 0.8 mm, and a proficient minimum fused deposition modeling (FDM) wall thickness is iii times the nozzle size, typically 3 ten 0.4 = 1.2 mm.

-

Horizontal bridges or spans over 21 mm require support material in SLA 3D printing. FDM 3D printers can normally reproduce around l mm bridges without supports.

-

With SLA 3D printers, wires tin exist very thin, up to twenty times the wire width. For example, with 0.3 mm thickness, you can impress up to seven mm tall before you start to see waving. 1.5 mm wires tin can go up to xxx mm tall without defects. Usable wires in SLS commencement at ane mm bore and in FDM at four times the nozzle width.

-

For embossed details, stick to a minimum of 0.4 mm depth for SLA and SLS, and 0.6 mm for FDM.

-

For parts that are close together merely crave a slight separation, stick to a minimum of 0.five mm clearance.

-

Go on overhangs to a minimum or at least below a certain threshold bending for 3D printing without supports. For SLA, the threshold is xix degrees while for FDM, 45 degrees minimum needs to be attained. SLS 3D printers require no support fabric since the powder bed is self-supporting.

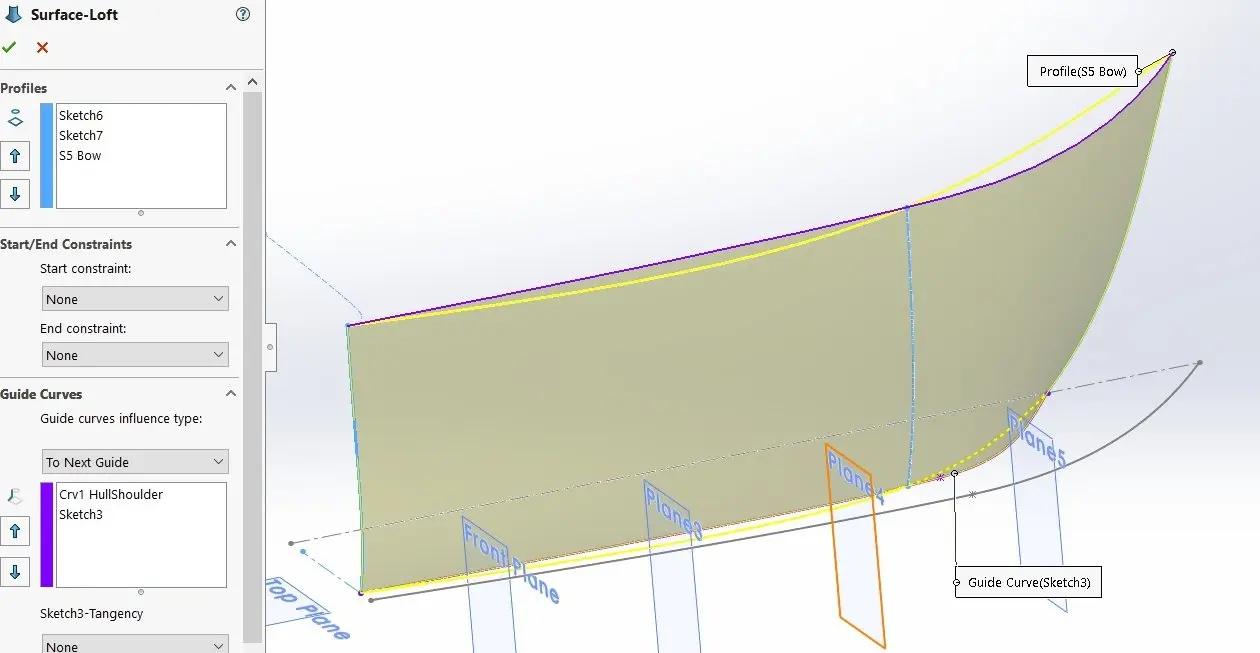

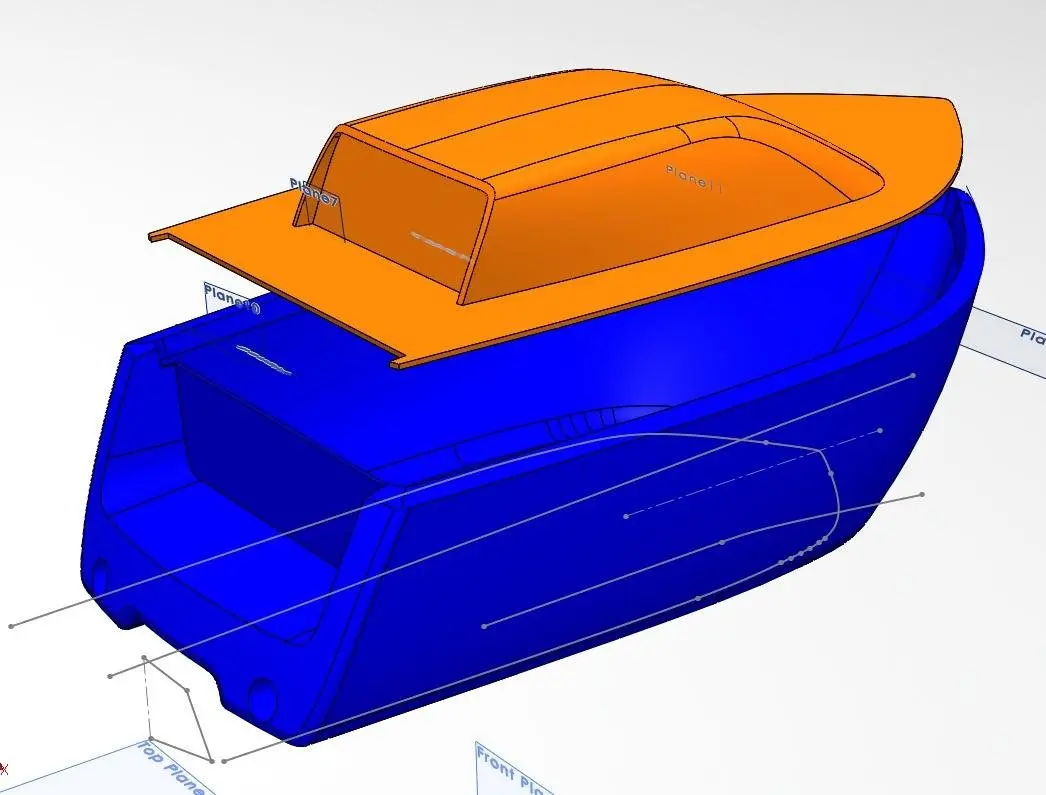

In our example, we are modeling a custom yacht model while keeping 3D press restrictions in listen. This model entails some relevant features that need to be controlled to keep the model 3D printable, while offer avant-garde modeling challenges. One of these is the hull. Because of inner architecture requirements and hydrodynamics, a boat hull needs to be tightly controlled at several sections and is therefore created using a surface loft with multiple profile curves at unlike planes along the length of the ship.

Our instance custom yacht model creating modeled in Solidworks.

To create the topmost curve of the hull, we employ the Projected Curve characteristic nether Insert → Curve → Projected and select the Sketch On Sketch method. This creates a 3-dimensional combination of two different curves that are oriented on different planes. For the hull, an outline of the gunkhole shape fatigued from the top was projected onto an upward sloping curve drawn from the side.

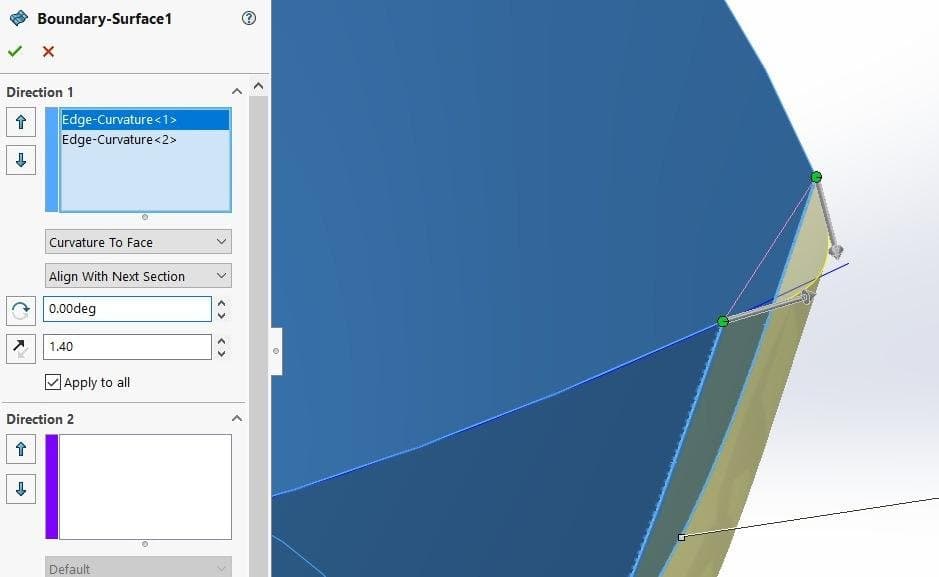

Lofting enables creating smooth surfaces through multiple profile curves.

This lofting operation uses strictly divers curves at all sides plus contour curves. Using this many curves has to be done carefully because it volition impact surface curvature. Another way to create surfaces is to create a loft betwixt two curves only. Keeping things simple often results in better quality surfaces, which in turn leads to more robust and high-quality models.

To control the lofting direction, use either i guide curve or Start/End Constraints which can exist set in the Loft carte du jour. When using a guide curve, the two contour curves are typically drawn on planes that are created perpendicular to the guide bend at its endpoints. When opting for Tangency or Curvature start and end constraints, use an extruded or ruled surface to define the lofting direction. Setting the commencement and end Tangent Length and so allows precise command. Using this method, intersections between unlike surfaces will exist less defined and accept to exist created afterwards using trims or split lines, but the advantage is superior surface continuity.

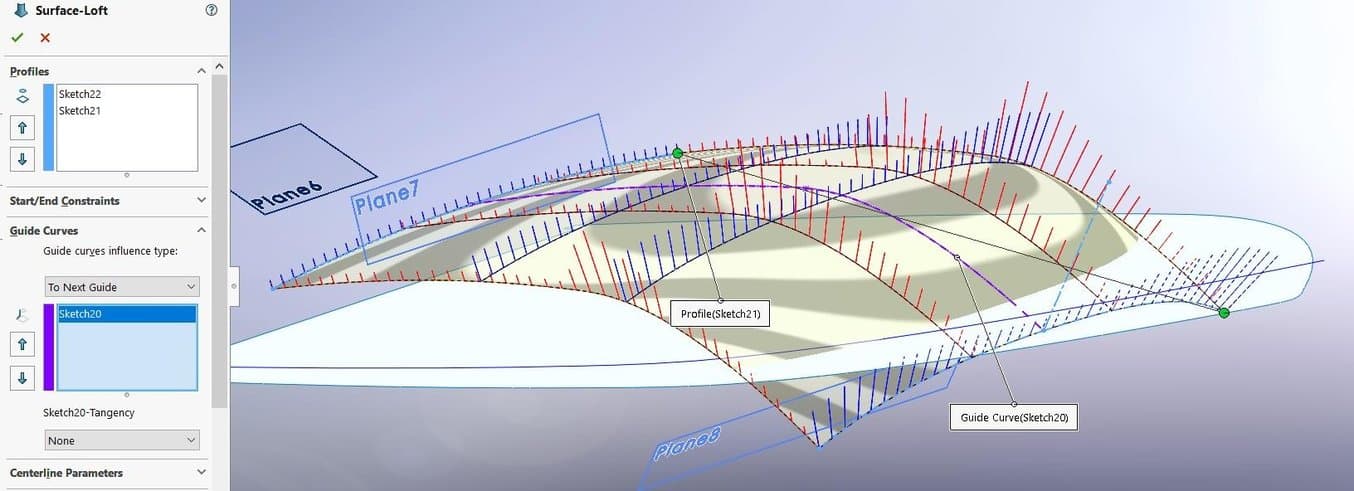

A sweep operation is similar in function to a loft simply uses one profile curve. A boundary surface is even more similar to a loft with the difference that information technology allows setting start/end tangency in both directions. The reward is more control but at the price of overall surface curvature.

Lofting Pro Tip #ane: To evaluate surface quality, cheque Curvature Combs and/or Zebra Stripes under Curvature Display at the bottom of the surface operation menu.

Lofting Pro Tip #2: In the 3D viewport, right-click and cull Prove All Connectors. This allows the user more command over how different curves are connected, preventing undesired occurrences such every bit torsions.

Lofting surfaces freely in space results in great surface continuity.

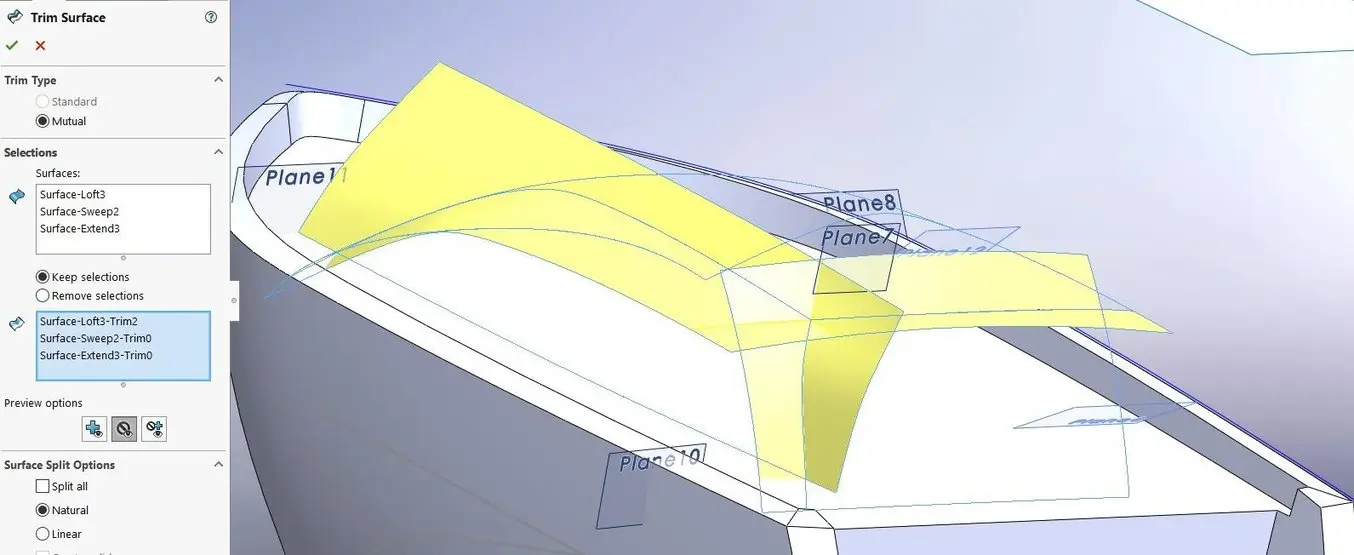

With the gross surfacing work completed, it is time to combine them together into volumes. In our yacht model, every side of both the hull and cabin superstructure has been created as a separate surface. Now when choosing Insert → Surface → Trim Surface, select the Mutual option and choose the surfaces to be combined. Then SolidWorks allows creating the parts of every surface to maintain or delete, and automatically stitching the remaining parts together into one single surface body.

Trimming different lofted and swept surfaces together into a unmarried volume.

All major surfaces have been created using lofting/sweeping so trimming operations.

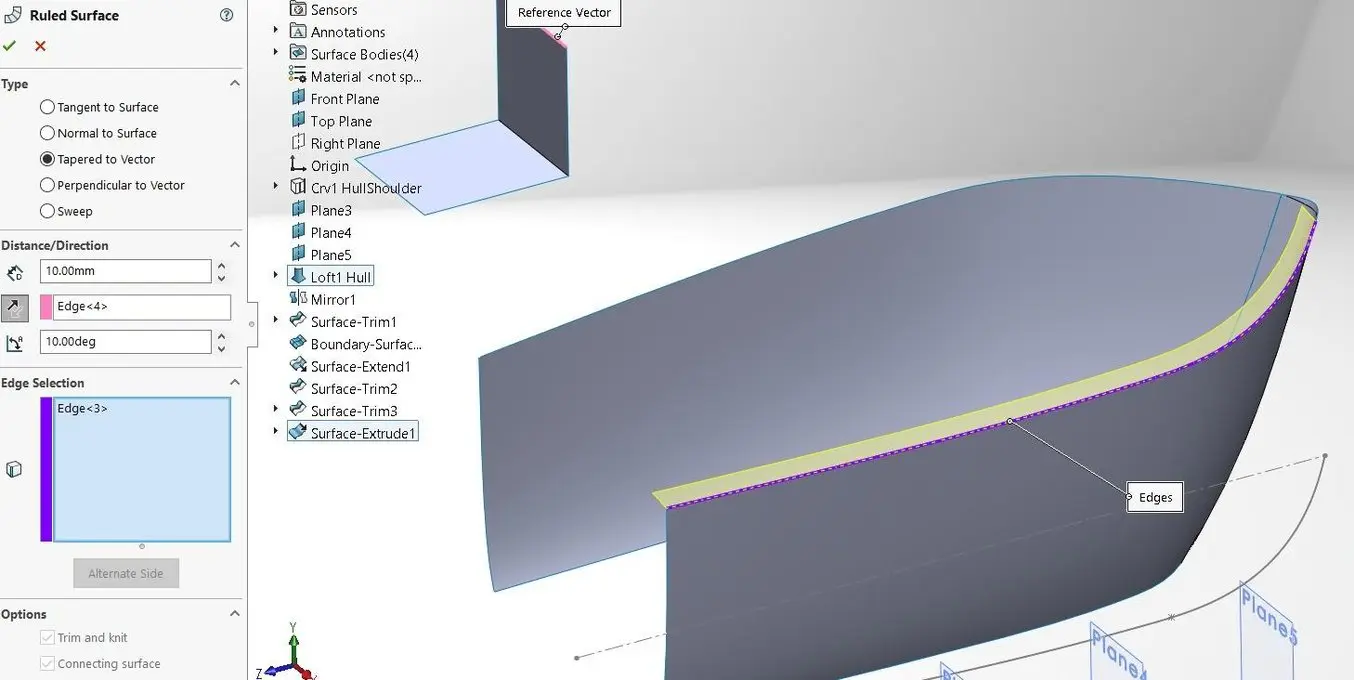

Creating an edge at an angle or perpendicular to the original surface is a popular pattern characteristic. The Ruled Surface characteristic under Insert → Surface → Ruled Surface allows that and offers the Tapered to Vector option. This allows picking a reference edge as the direction vector and specifying an angle at which the ruled surface will be generated in relation to the reference vector. In the yacht model, both the edge providing thickness to the top of the hull and the edge moving downwards to connect with the deck were created using a ruled surface. An alternative to the ruled surface is Radiate (Insert → Surface → Radiate). This creates an edge perpendicular to the base surface post-obit an edge or split line on that surface.

The Ruled Surface operation offers several options to create flanges.

Adding fillets to a 3D printable model is recommended because they make the part stronger and less prone to fissure forming. Additionally, they likewise catch the calorie-free and add to the aesthetic impression.

There are many means to add together fillets to a design:

-

Edge Fillet: Circular

-

Edge Fillet: Conic Rho

-

Edge Fillet: Conic Radius

-

Edge Fillet: Curvature Continuous

-

Variable Radius Fillet

-

Confront Fillet

-

Full Round Fillet

-

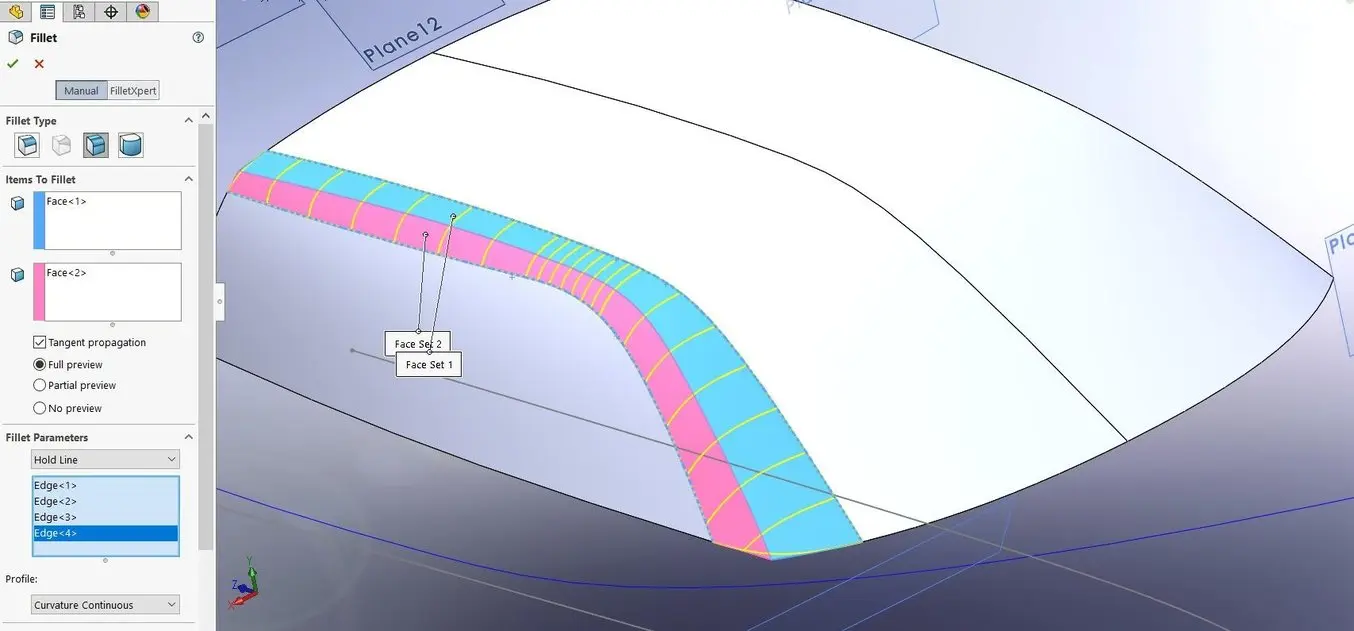

Agree Line Fillet / Blend

A Circular Fillet is the nigh basic, also computationally speaking. Over 5 mm in size information technology will result in a visible line on manufactured items as an optical upshot where the surface meets the fillet—for 3D press the maximum radius is slightly college considering the surface roughness hides imperfect surface continuities. The reward of using Edge Fillets is that every fillet tin can be simultaneously applied to multiple edges, whereas other fillet types have to be individually created for every edge.

Conic Fillets have become increasingly popular among CAD designers as the next all-time thing considering they result in a smooth blend while being computationally lightweight. The Conic Rho parameter here allows setting the 'peakiness' of the fillet.

Curvature Continuous Fillets are the virtually computationally intensive simply result in the highest quality.

A Variable Radius Fillet allows transitions in radius inside the same fillet. This comes in handy when the fillet ends in a tight cusp where a very low or zilch radius fillet works and other types of fillets fail.

A Face Fillet creates a rounding between specified faces rather than edges–in some cases this results in a more robust fillet operation. Checking the option Constant Width sometimes creates better results.

The Full Round Fillet is a specific type of face fillet that creates a full circular rounding between three faces such as the crosscut side of a sparse solid. When modifying the geometry, the full round fillet automatically scales forth.

A Agree Line Fillet is a variation of the face fillet where not only the radius is specified, but also the lines where the surfaces involved meet the fillet. This simply works on solid bodies and the use of carve up lines typically results in successful hold line fillets. In case the surface is difficult to convert to a solid first for creating the hold line fillet, an alternative approach is cutting the surface open with trim lines, then blending the open sections together using a Loft functioning and using Insert → Surface → Knit to combine all surfaces back into a single surface body.

Use Hold Line Fillets to create big blends betwixt surfaces.

The bow front end was filleted with a surfacing characteristic to optimize curvature.

It is preferable for 3D printing to create thin-walled models, because these likewise define the within of the model instead of leaving it up to slicer software to create infill and wall thicknesses. When modelers take attained a complete surface model, information technology is necessary to convert these into solid bodies. Ornamental details such as fillets and embossing are added afterward since these may impede the solidification process.

There are multiple workflows to become almost converting surfaces to solids:

-

Knit to Solid: When all surfaces connect to enclose a book, cull Insert → Surface → Knit Surface, and then check Create Solid.

-

Thicken: Choose Insert → Boss/Base of operations → Thicken, cheque Create Solid from Enclosed Book to generate a closed solid body, uncheck information technology for a sparse shell.

-

Trim to Solid: When all mutually trimmed surfaces result in an enclosed volume, these can be immediately converted to a solid past ticking the box Create Solid.

-

Offset: Create an showtime surface that represents the inner wall with Insert → Surface → Offset. So it is possible to connect the edges using the Loft control. Now, instead of selecting a single edge, select the unabridged border boundary loops by right-clicking on the container box in the bill of fare under Profiles and choosing SelectionManager. Make certain to accept the get-go points of both edge loops at an adjacent position and you lot will be able to loft the entire connection in one dive. With the inner surface and connecting edges selected, they can now be converted to a solid with a Knit to Solid procedure. An culling to lofting is creating a ruled surface at an angle so information technology intersects the inner surface, then using the Trim to Solid approach.

-

Shell: Subsequently having created a solid from an enclosed surface volume, thin walls can be achieved with Insert → Features → Shell. This starts an advanced script that creates a hollow solid role prepare for 3D printing.

For our 3D printed yacht, the deck including the superstructure is printed equally a separate function from the hull. This is a logical separation because both parts have a flat surface that will largely print without any support textile. Where surfaces include only large fillets without pocket-sized details, the Thicken operation works well.

Surface bodies are turned into thin-walled solids with the Thicken command.

In several cases, designers and engineers want to create split solid bodies, for example when applying unlike wall thicknesses to different parts of the model. To merge solids with each other, SolidWorks offers Boolean operations under Insert → Features → Combine. To unify multiple parts into one, choose Add. Subtract volition cut out one shape from the other, while Common leaves only the part where multiple bodies overlap.

In Associates Mode, it is also possible to combine separate parts with the Join feature. First, create a new part with Insert → Component → New Part, then click Insert → Features → Bring together. This volition unify selected parts within the assembly at their current position and orientation into 1 single trunk.

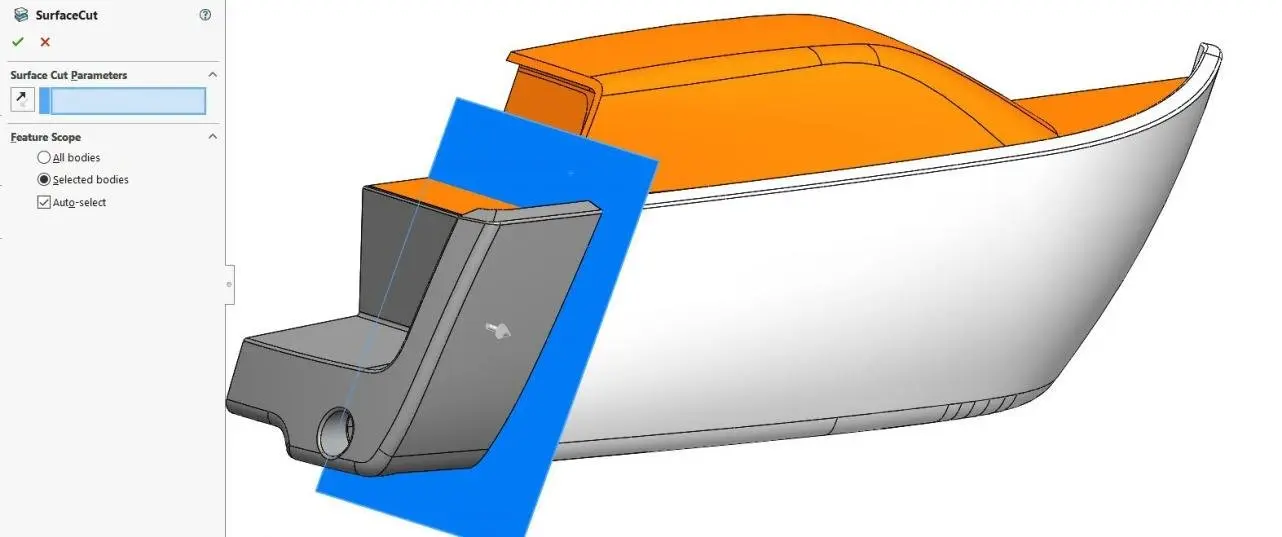

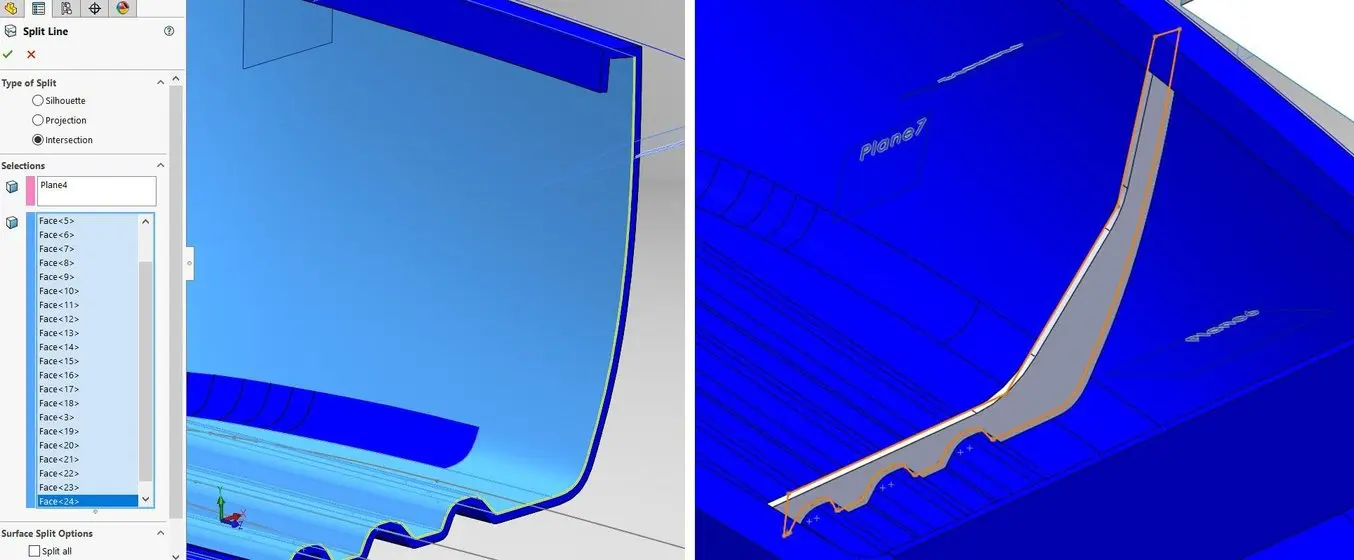

The all-time way to carve up a solid body into 2 sections is by using the Split command nether Insert → Features → Carve up. First, create the cut surface—it can have any shape and can fifty-fifty exist a sketch. Then hit Cutting Function and make up one's mind in the Resulting Bodies panel which ones to keep. In case of requiring only one office to be retained, an alternative is the Cut with Surface command nether Insert → Cut → With Surface.

Pro Tip: Save out an individual body of the blueprint equally a separate SolidWorks .SLDPRT file with Insert → Features → Save Bodies. To go on a reference to the original part and then that the pattern will be automatically updated in sync with the original model, create a Derived Part by right-clicking the body in the FeatureManager and select Insert into New Part.

A cut surface divides the model into two separate solids.

For parts of the model that are spaced apart, leave at to the lowest degree 0.five mm clearance to ensure they do not fuse together during 3D press. When 3D printing multiple parts that need to exist fitted together, such as the hull and deck in our project, it is important to adhere to good tolerancing practices. For a snug fit, leave 0.25 mm clearance for parts created with FDM, and 0.15 mm for SLS, and SLA.

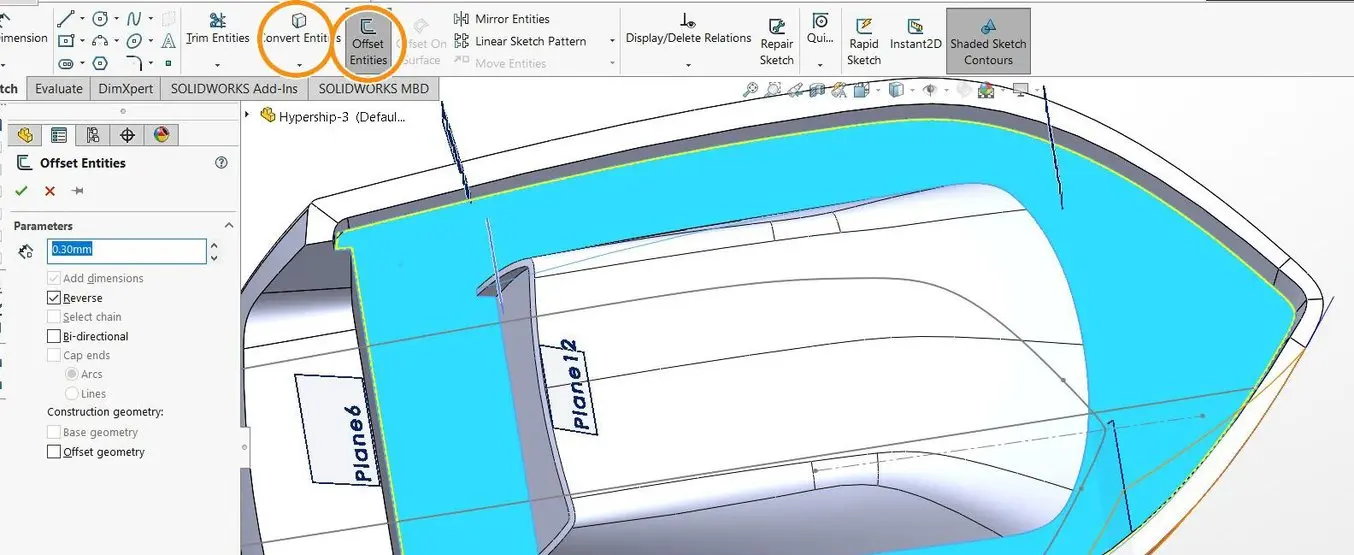

Offsets are the go-to way for creating distances between related features. Likewise offsetting surfaces (Insert → Surface → Offset) it is also possible to create a sketch as an outset from an existing sketch or edge. To offset a sketch, open up a new sketch, select the original one, and click on Showtime Entities. For offsetting only a part of the original sketch, or offsetting edges in the model, kickoff import these to your sketch with Convert Entities. With the imported entities selected check Construction Geometry to indicate that these are not the sketches to be used for the feature but an in-between pace. Now select the parts to beginning and hit Start Entities.

Utilize Commencement features for creating clearances between different 3D printed parts.

Offsets are also good for negative clearances, that is when features need to overlap. Consider for instance the case of calculation ribs to the inner hull. Ribs are an accessible method to add together strength to the role at specific locations. For any curved surface, we cannot simply draw a curve on the surface and extrude it to create a rib, because it would not connect to the original surface in all places. To ensure a consistent overlap, we need to offset information technology into the solid body just enough so the extrusion volition overlap on all sides. An offset curve tin be created at a section aeroplane to the original surface, then using the Intersect choice under Insert → Curve → Split Line and selecting the department plane and surface. Now create a new sketch on the section plane and offset the divide line to create the start curve. Finally, describe the unabridged feature so it can be extruded.

A negative offset creates overlapping features that tin be merged into a single role.

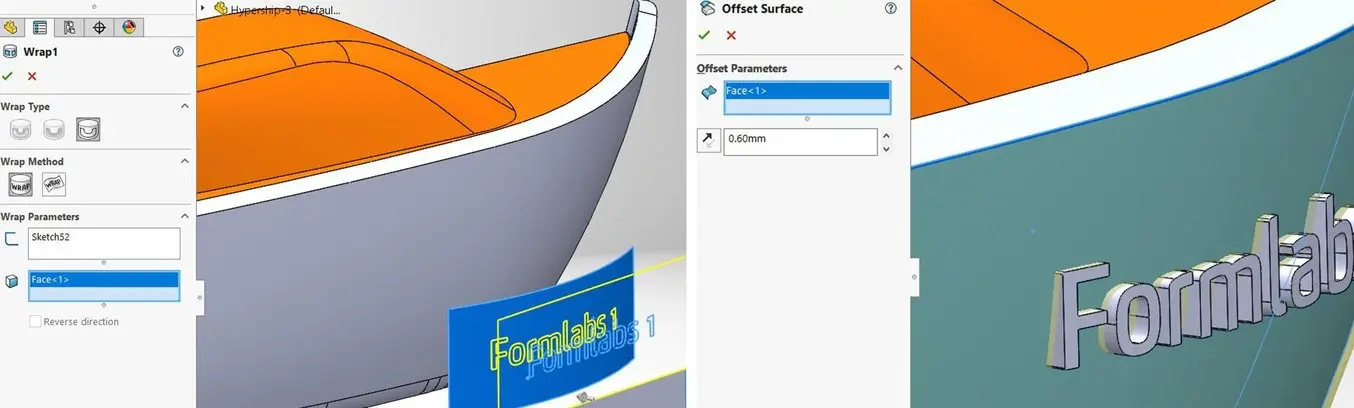

SolidWorks provides ample opportunities for adding iii-dimensional text features to a design. Near font types volition be readily convertible into SolidWorks, with a preference for Sans Serifs. Lettering can be added to a sketch using Tools → Sketch Entities → Text. Text can exist mapped to follow a curve, it tin be mirrored, and private letters tin be rotated under a specified bending.

A specific method applies to mapping text onto curved surfaces: text wrapping. This repositions text drawn on a planar surface onto a curved, preferably cylindrical, ane. In club to estimate the hull's shape, draw an arc sketch on the top plane all-time matching the curvature of the hull, then extrude the sketch. Create the text characteristic on a airplane or planar surface facing the curved extrusion. Now wrap it onto the cylindrical surface with Insert → Features → Wrap. The text is now scribed onto the surface and divides it into unlike faces. If we delete the faces surrounding the messages too as the openings (known as 'eyes' in typography), but the letters remain. These will then be individually converted into a solid using the Thicken control and positioned onto the hull with Insert → Features → Move/Re-create.

Now with an starting time of the hull surface and the Cut with Surface control as mentioned in the section Working with Multiple Solids, the text tin can be cutting then its outer surface exactly follows that of the hull. The reason why we did not pick the more than advanced Spline Surface wrap method is that using a cylindrical wrap maintains the horizontal orientation of the text where otherwise it would be oriented downwards along the hull's normal vectors. Note that when wrapping straight onto a solid body, it is possible to immediately emboss or deboss the text into the solid.

Pro Tip: Use a maximum sideways protrusion of 1 mm for lettering for back up-complimentary 3D printing. The minimum legible detail for SLA 3D printing is 0.1 mm for embossing and 0.4 mm for engraving, 0.35 mm for SLS, and 0.vi mm for FDM.

The wrap office offers advanced ways of adding text to surfaces.

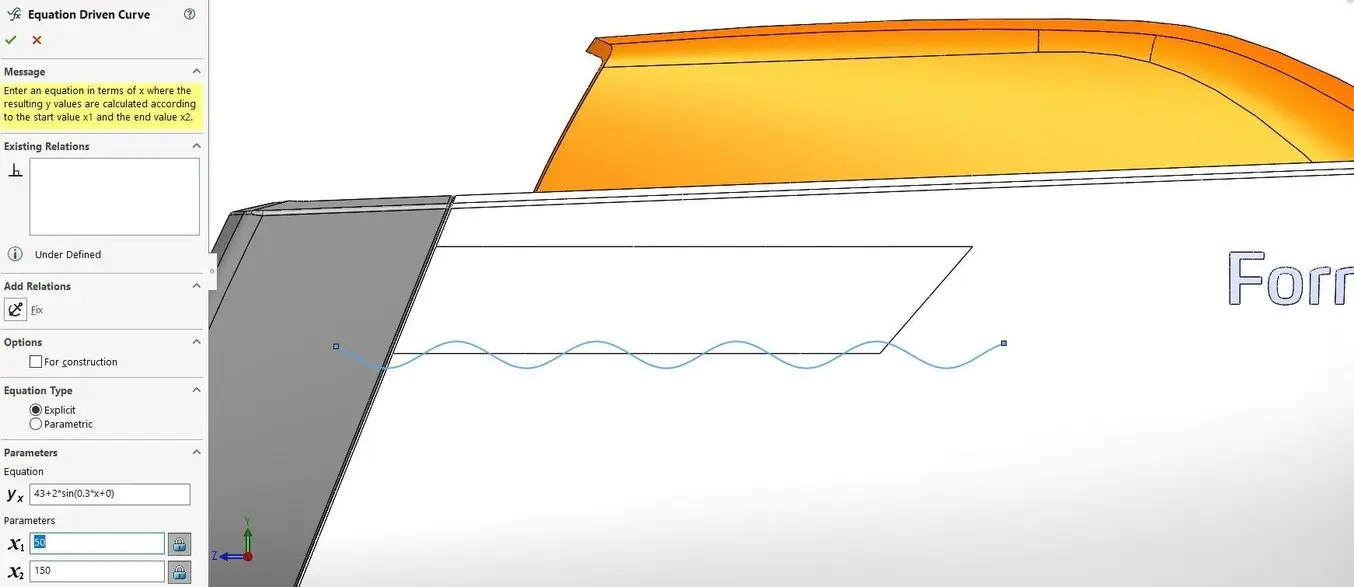

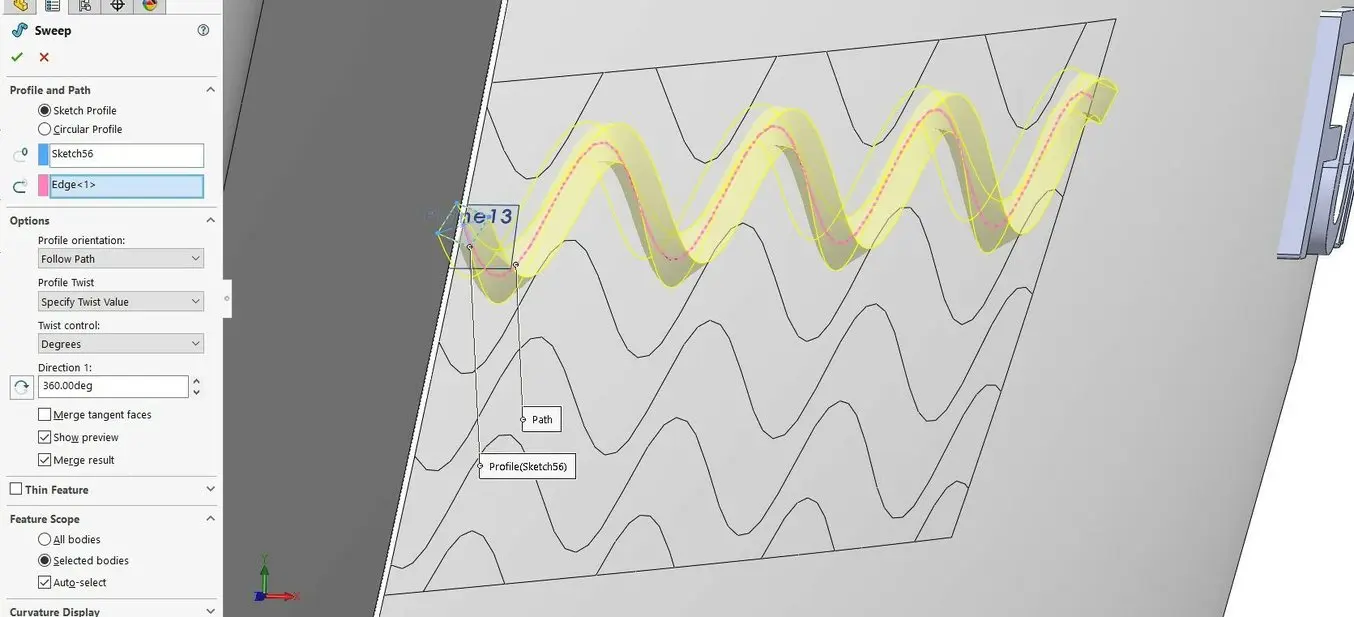

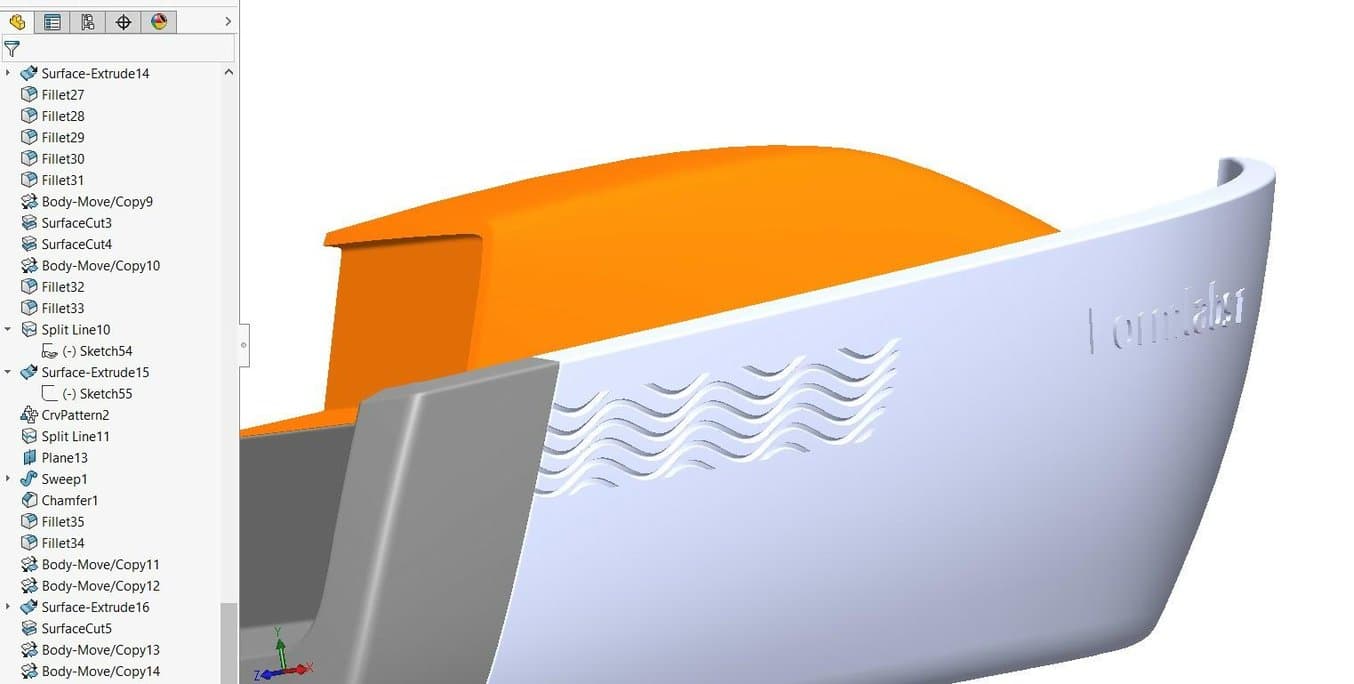

The preferred way of creating grooves on a solid body is the Sweep functioning under Insert → Cut → Sweep. Every sweep needs a guide bend and profile curve. A guide curve on a planar surface can exist directly sketched onto that surface, only for a curved surface, nosotros need to create a projected curve or split up line. The option Round Profile merely creates a tube along the guide curve. With the option Solid Profile, it is possible to choice a solid torso to generate the cutting and emulate a CNC cutting tool. With a custom Sketch Profile, it is possible to install an boosted twist value, then the terminate of the swept groove will be at a unlike specified angle than the offset.

In our instance, we have swept a square over a sinusoidal split line on the boat hull. The foursquare is positioned at a 45-degree angle relative to the guide bend in order to enable printing without stark overhangs. For an verbal design, every split line volition take to be provided with its ain sweep. For the small cut off elements at the edge of the patterning area, it is acceptable in some cases to copy and translate the nearest swept solid trunk, and cutting it with the curve that defined the original patterning area using the Cut with Surface control.

Pro Tip: The sinusoidal curve was created by choosing Equation Driven Bend nether splines in the sketch tab. This allows designers to input XY functions that direct generate a spline. For an advanced option, it is possible in SolidWorks to set up a set of variables and drive these using Excel worksheets.

Use Equation Driven Curve for mathematically defined sketches.

Twisted sinusoidal sweeps making for a iii-dimensional graphic area on the hull.

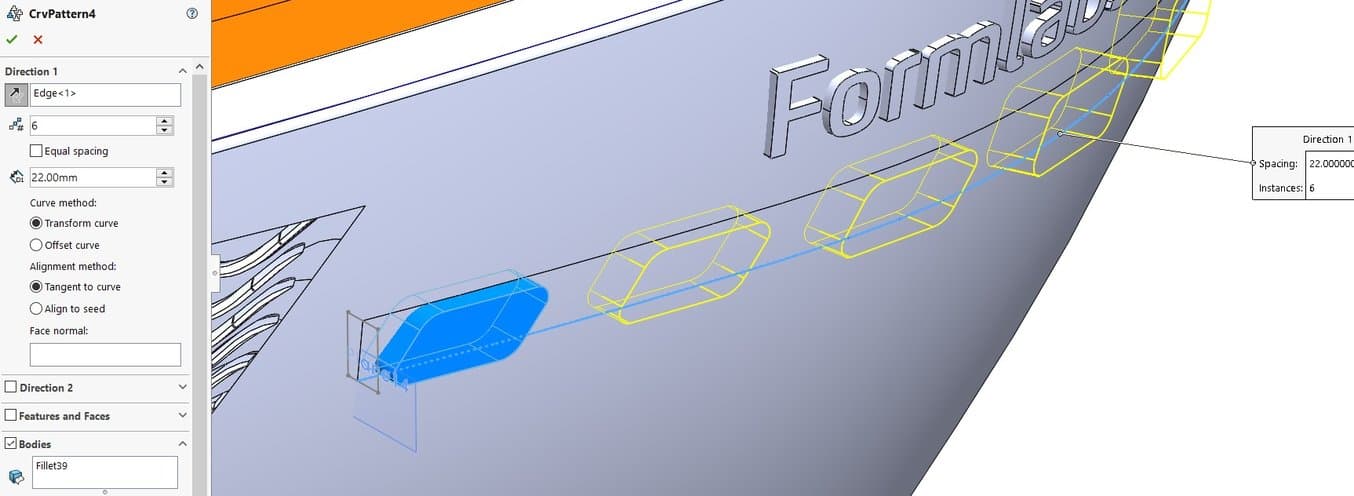

Designing patterns manually can be a bit dull. In SolidWorks, information technology could not be simpler creating a linear or rotational blueprint of an object or feature with the Insert → Pattern/Mirror → Linear Blueprint and Insert → Pattern/Mirror → Round Pattern commands. Information technology is as well possible to provide a numerical linear translation or rotation when using the Insert → Features → Motion/Copy command and ticking the Copy box with the number of copies chosen.

If we project a bend onto a solid body every bit a Split up Line, we can blueprint another solid body such as a window forth that bend, fifty-fifty maintaining the normal direction to correctly orient every case on the curve. To practice that, choose Insert → Blueprint/Mirror → Curve-Driven Blueprint and tick the radio box for the Tangent to Curve alignment method. If spacings demand to be uneven, it is possible to ascertain the locations using points in a separate sketch and opting for a Sketch-Driven Pattern under Insert → Design/Mirror → Sketch-Driven Design. Going beyond that, it is even possible to generate betoken locations within a sketch by linking a mathematics-driven Microsoft Excel sheet or from a text file containing the coordinates using the Insert → Design/Mirror → Table-Driven Design functioning. This type of parametric command enables designers to generate the geometrically complex and organic features that 3D printing excels at.

Bend-driven patterns work to create repeated elements on a complex shape.

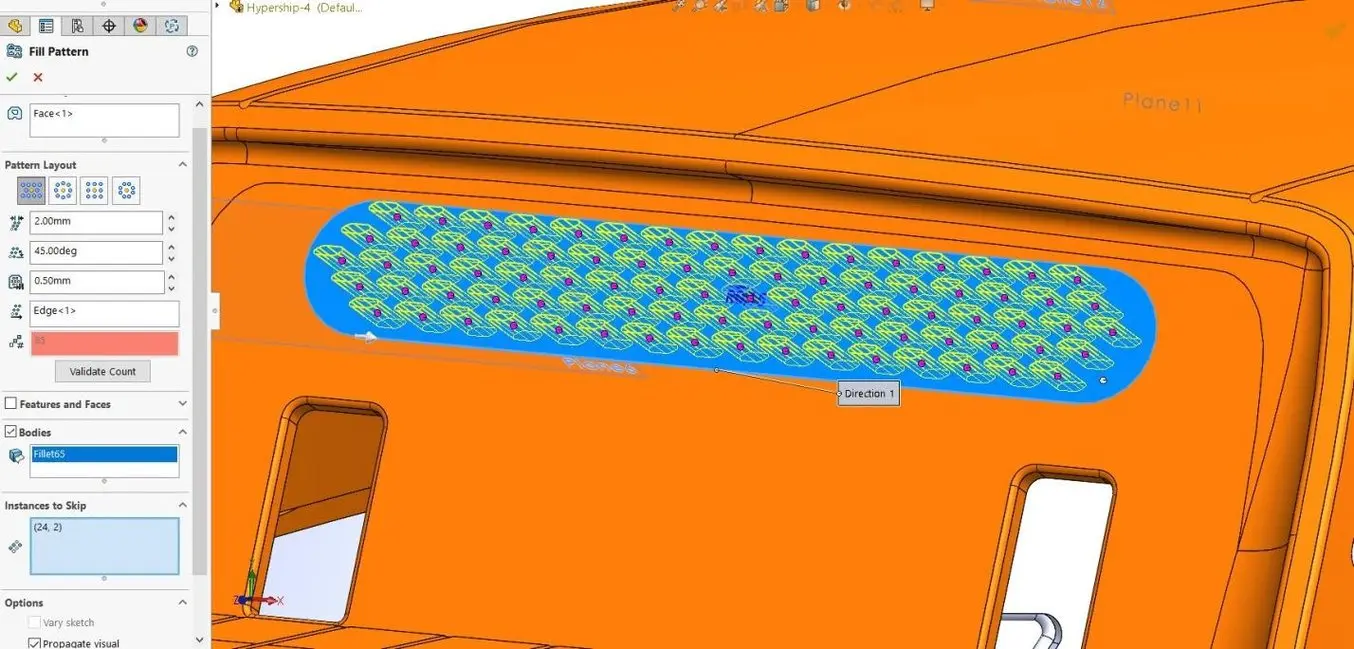

Another dainty feature is the Fill Blueprint, accessible nether Insert → Design/Mirror → Make full Design. The first step is to define an area to be filled with patterned elements. Adjacent, choose a patterning layout and spacing dimensions. This is an automated way to create graphically interesting perforations for parts like speakers, air vents, and showerheads. Further customization is possible by selecting the Instances to Skip at the bottom of the Fill up Pattern menu.

Make full Pattern automatically generates graphically interesting perforations.

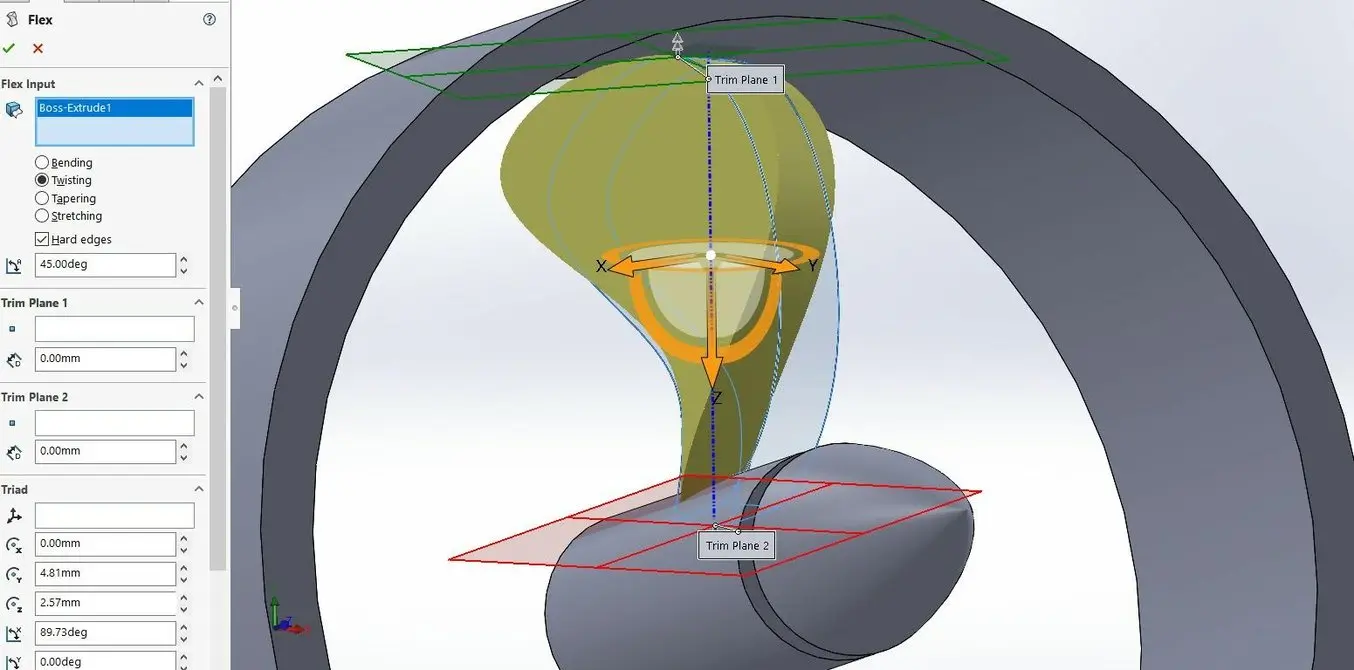

The Flex characteristic is an odd one out in SolidWorks because it is not driven by sketches, and yet, it results in workable geometry that cannot exist generated otherwise. Accessing it under Insert → Features → Flex enables the designer to curve, twist, taper, and stretch solid and surface bodies after they have been modeled. These features as well stack up successively for increasingly complex surfaces. Boosted control on the center pivot location of the twist, taper, or bend tin exist accomplished using a control triad. This requires creating a Coordinate System reference first past clicking Insert → Reference Geometry → Coordinate System. The triad can be relocated past selecting an element to move it to in the 3D viewport, and so hitting the right mouse button on the center of the triad, and so Movement to Selection. Moving the Trim Planes then allows bending only a specific portion of the model.

Some other post-surfacing operation is Freeform (Insert → Features → Freeform), where the designer can add control points on section curves across a complex surface. These points, equally well equally the start and end curvature direction of the section curves, tin then exist individually modified allowing organic and unusual surface shapes to be made.

Deform, under Insert → Features → Deform, will morph a shape from a reference point or surface, in a particular direction and with a specific elasticity (the Stiffness option). The Curve to Bend mode accurately transforms 1 bend inside the part to a newly created curve then the part gains an entirely new shape. In Surface Push mode, a separate surface is used as a stamp that virtually deforms the part by pressing into it.

Flex is a postal service-processing operation to bend, twist, and taper bodies like this propeller.

Source: https://formlabs.com/blog/solidworks-tutorial-3d-printing-modeling-inspection/

0 Response to "solidworks 3d part to 2d drawing"

Enviar um comentário